From the shop floor to field installation...

Our manufacturing group is CWB Certified in both steel (W47.1) and aluminum (W47.2) with GMAW, SMAW and GTAW procedures.

What began as vertical integration of our substation design-build business, has grown to see quality products and services provided to the utility, steel, potash, grain, and fertilizer industries, as well as production support to other fabrication companies.

Our range of services has extended to E-house manufacturing, industrial facility site welding, and maintenance support. Now with the addition of one of the province's largest Plasma Cutting tables, our shop services allow even greater custom manufacturing capabilities.

Our team works with your team and integrates into your systems to better meet your power, protection and control requirements.

Steel and Aluminum Fabrication

- Substation structure fabrication

- Structural steel and aluminum platforms, stairs, pipe racks, etc.

- Foundation pile caps (plates)

- Copper-to-steel welding

- Custom fabrication

Field Services

- Substation structure erection

- Aluminum bus welding

- On-site steel, aluminum, and stainless steel welding services

- Structural steel welding, installation, and repair

- Transformer repair

- Custom solutions

E-Houses and Custom Shop Services

- Custom E-Houses

- Mining box fabrication and modifications

- Steel, aluminum, and stainless steel welding

- Custom control and cable termination boxes

- Process control equipment and skids

Plasma Table

- 12' by 48' Plate Storage Bed

- Mild Steel up to 2.5" thick

- Aluminum up to 6" thick

- Stainless Steel up to 6" thick

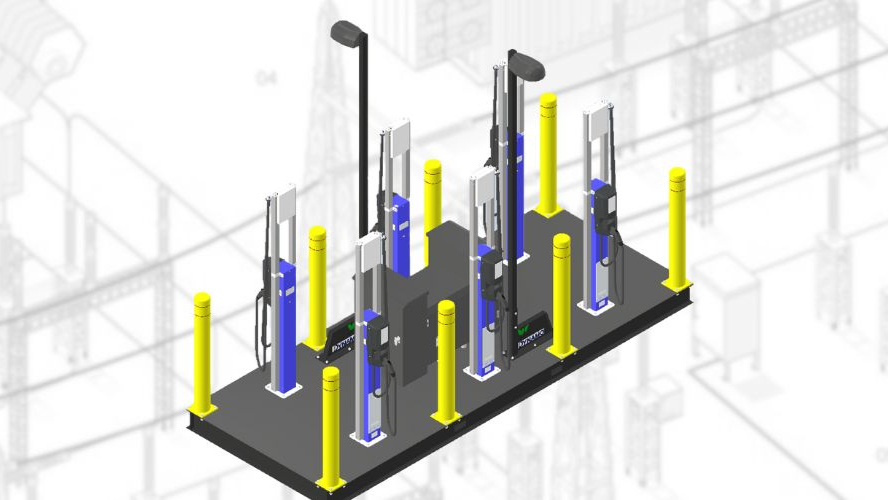

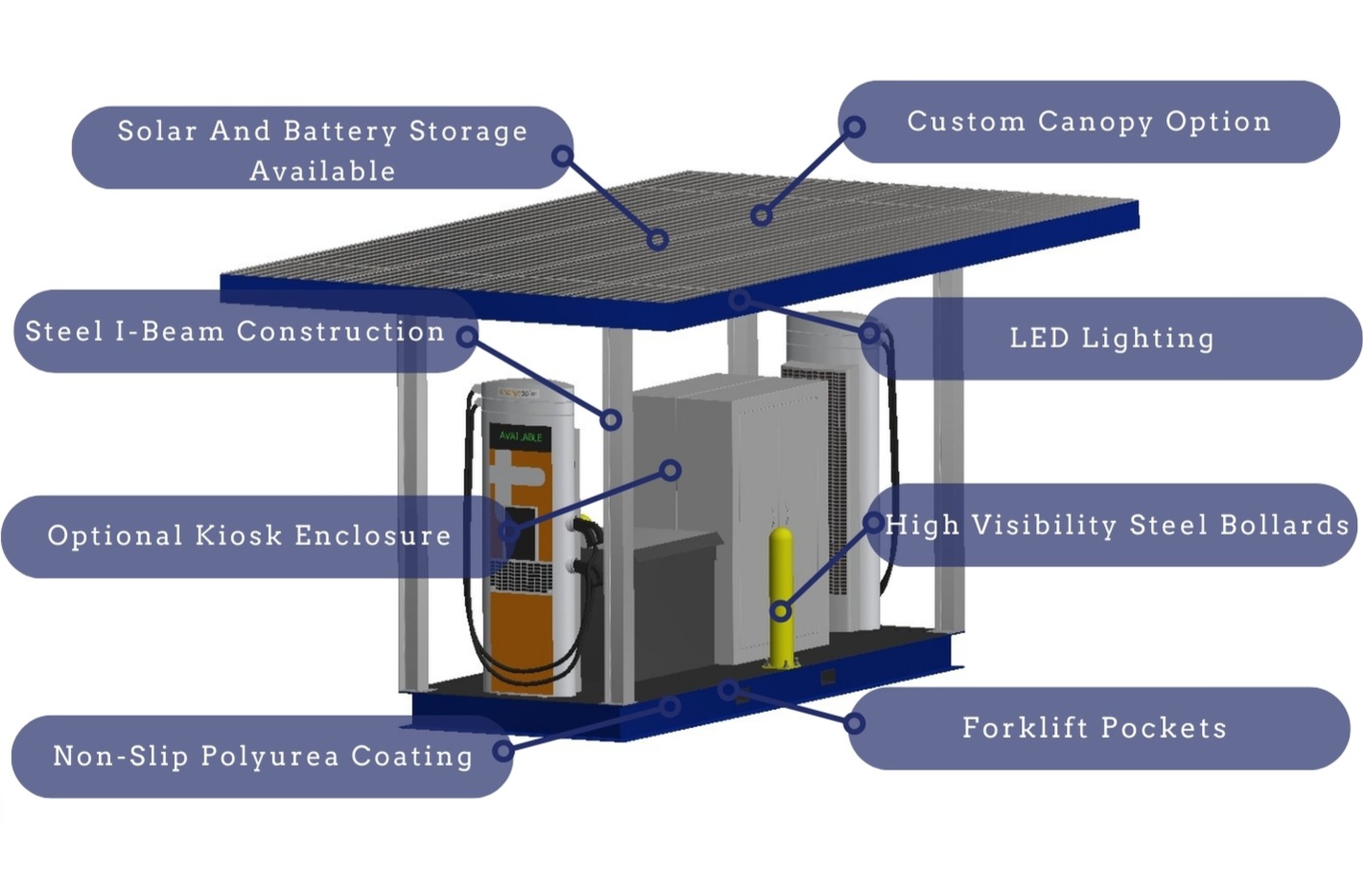

Accelerate EV charging instillations with pre-fabricated skids

As EV adoption continues to advance, so must charging infrastructure deployments.

Taking into account administrative, civil, and electrical work, deploying an EV charging sites can take weeks or months to complete. By prefabricating and certifying charging sites at the factory, installations can be completed in just days.

The Canadian-built skids are entirely modular, fully customizable, and safety certified at the factory; ensuring safe and reliable solutions for both Level 2 and Level 3 EV charging sites.

All power distribution, lighting, and safety equipment are included alongside the charging stations and can be entirely customized to suit your site needs.